Our Services

Expert welding services,

delivered to you

Aluminium Welding

Whether you have a small precise aluminium job or large structural beams, we can cover all your needs. We specialise in MIG, TIG, Arc welding and plasma cutting across all metals. Welding standard is minimum AS1554.

MIG, TIG & Arc Welding

Our team have nearly three decades of experience with MIG (metal inert gas method), TIG (tungsten inert gas method) and Arc (electric) welding. Each is used for different kinds of projects and different types of metal, and our team can offer you advice on the right technique for your unique job.

For each technique, we utilise cutting-edge technology and tools to ensure that your project is completed with the highest level of care and you the best results.

On Site Plasma Cutting

Plasma cutting is widely used in various industries for cutting a wide range of materials, including steel, stainless steel, aluminium, copper and other conductive metals. Our team are highly trained in using this technique, and because we have a mobile plasma cutter, we can bring our work to you.

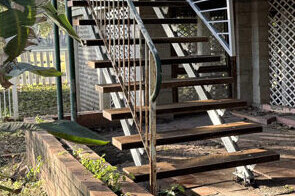

Plant and Machinery Welding

Whether you have equipment in a manufacturing plant or heavy machinery on a construction site, our team of mobile welders are the experts you need to handle the job quickly and efficiently. And because we are mobile, we can bring our services to you, ensuring that you get the work you need done in a timeframe that best suits you.

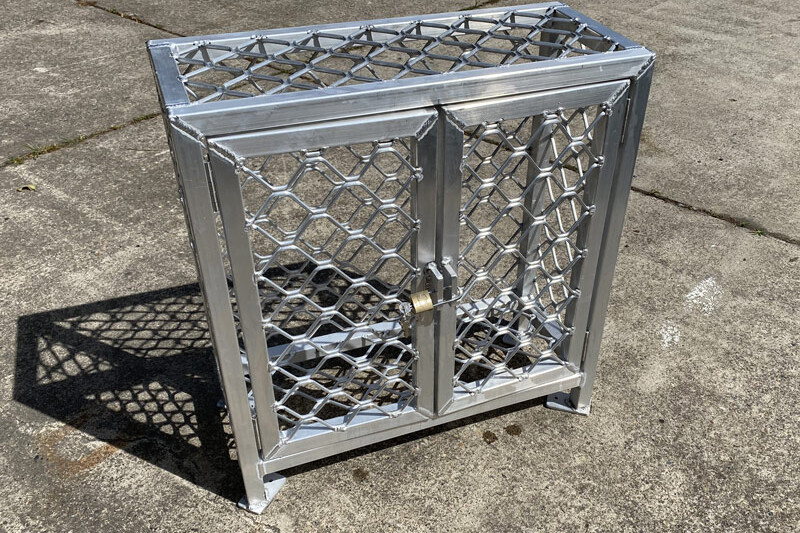

Custom Fabrication

You have the idea and we’ll make it a reality. Custom fabrication lets you design exactly the product you need in exactly the way you need.

Examples of our custom fabrications include trailer and caravan attachments, custom gates, boat attachments, gym equipment, medical tools and drone trolleys.

FAQs

Aluminium welding is the process of joining pieces of aluminium metal together using various welding techniques. Aluminium is a lightweight and corrosion-resistant metal commonly used in a wide range of applications, including automotive, aerospace, construction, marine applications and more.

Welding aluminium can be challenging compared to welding steel because of its lower melting point and higher thermal conductivity. It also comes in various alloys with different properties. It’s crucial to know the specific alloy you are working with as different alloys have different welding characteristics. Common aluminium alloys include 6061, 5052 and 7075.

MIG welding (or metal inert gas welding) is typically used for mild steel, stainless steel and aluminium materials. MIG works by continuously feeding welding wire that burns and fuses and ultimately combines the metals together. This is one of the most common welding methods used.

TIG welding (or tungsten inert gas welding) is mostly used for thinner materials and can also be used for very light gauge material like kitchen sinks or tool boxes. TIG is a slower method that takes more skill and time, but is used for more precise and delicate welding jobs.

Arc welding (or electric welding) is mobile and versatile and is typically used for our on-site welding. It has its own built in shielding gas produced from electro burn.

Plasma cutting is a metal cutting process that uses a high-velocity jet of ionized gas, known as plasma, to melt and remove material from a workpiece. This process is widely used in various industries for cutting a wide range of materials, including steel, stainless steel, aluminium, copper and other conductive metals.

Welding in the context of plant and machinery refers to the process of joining metal components or structures used in various industrial settings, including manufacturing plants, construction sites and heavy machinery maintenance and repair. Welding plays a crucial role in maintaining, fabricating and repairing the equipment and machinery needed for various industrial processes.